Background

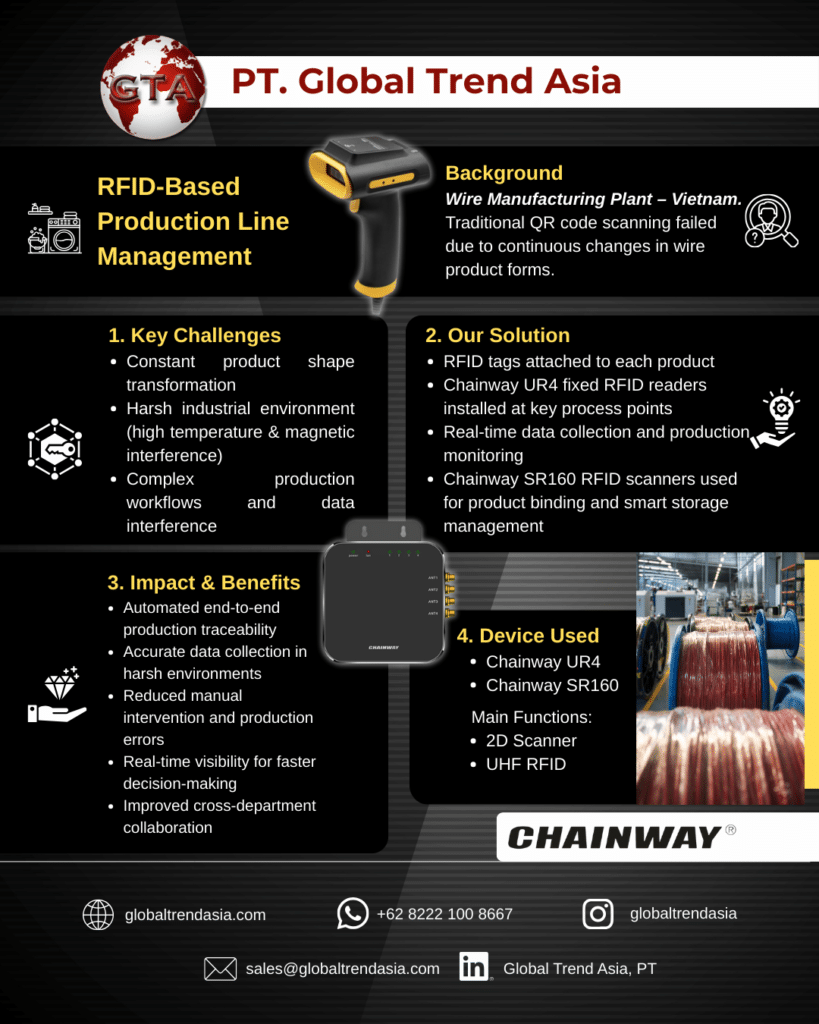

In modern wire manufacturing plants, maintaining production efficiency and accurate traceability is a major challenge. At a wire manufacturing facility in Vietnam, traditional QR code scanning methods proved ineffective due to continuous changes in wire shapes and product structures throughout the production process. To overcome these limitations, the factory implemented an RFID-based production line management system to ensure seamless monitoring, traceability, and quality control.

Key Challenges

The production line faced several operational obstacles. Constant product shape transformation made fixed barcode or QR code scanning unreliable. The harsh industrial environment—characterized by high temperatures and strong magnetic interference—required highly durable and high-performance devices. In addition, complex workflows and overlapping production processes caused data interference, reducing the accuracy of manual data collection.

Our RFID Solution

PT Global Trend Asia, in collaboration with Chainway, deployed a comprehensive RFID-based automation solution. RFID tags were attached to each product, enabling identification throughout the entire production lifecycle. Chainway UR4 fixed RFID readers were installed at critical process points to capture real-time data automatically. For product binding and smart storage management, Chainway SR160 handheld RFID scanners were utilized, supporting both UHF RFID and 2D barcode scanning.

Impact & Benefits

The implementation delivered full end-to-end production traceability with real-time visibility across departments. Data accuracy improved significantly, even in extreme industrial conditions. Manual intervention and production errors were reduced, enabling faster decision-making and better cross-department collaboration. Overall, the RFID system enhanced productivity, quality control, and operational efficiency.

Sales & Marketing

Phone: +62 8222 100 8667

Email: sales@globaltrendasia.com