Background

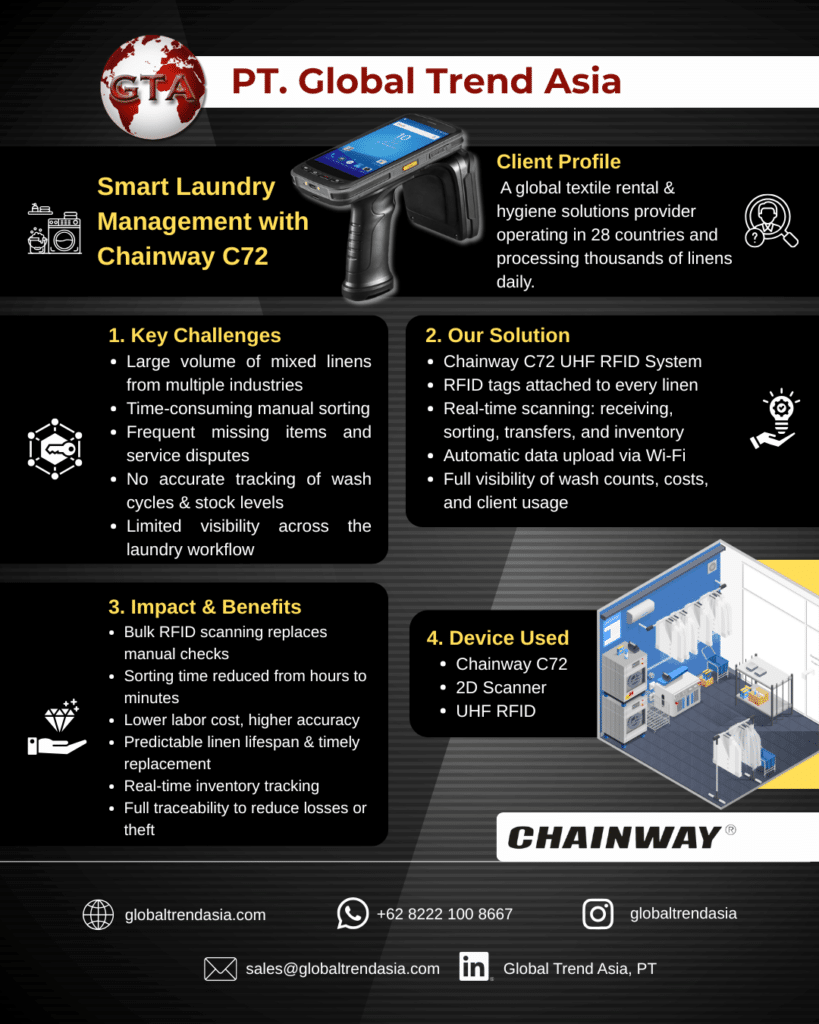

One of our clients—among the world’s leading providers of textile rental and hygiene solutions—operates across 28 countries in Europe and Latin America. With more than 45,000 professionals working in over 440 production and service centers, they serve more than 400,000 customers worldwide. Every day, their laundry facilities process thousands of workwear items, towels, tablecloths, and bed linens. Managing such massive volumes makes efficient inventory control and laundry process tracking a significant operational challenge.

Challenges

The client handles a vast number of linen types sourced from hotels, hospitals, spas, and rental companies. Traditional sorting requires high manpower and time, while also increasing the risk of errors and item losses.

Given the diversity of customers and products, missing items frequently occur during the laundry cycle, resulting in financial losses and service disputes. In environments such as hospitals—where cross-contamination concerns limit manual counting—the number of items to be washed cannot always be confirmed accurately, further complicating handover processes.

Additionally, without an efficient tracking system, it becomes difficult to monitor wash cycles, usage frequency, stock levels, and linen categories. This can lead to overlooked items, stock shortages, and disruptions in daily operations.

Solution

To address these issues, Chainway deployed its UHF RFID solution to enable intelligent linen management. Each piece of linen is equipped with an RFID tag, and staff use the Chainway C72 handheld reader to scan items throughout every stage of the workflow—receiving, transferring, sorting, storing, and counting.

All process data is collected automatically and transmitted in real time to the backend system via Wi-Fi. This allows managers to monitor wash counts, washing costs, rental quantities, and customer-specific usage. Equipped with a self-developed RFID module, the Chainway C72 delivers full visibility of the laundry lifecycle and supports data-driven decision-making.

Results

With Chainway RFID readers, linens are identified automatically and in bulk, replacing manual handling and significantly improving speed and accuracy. Tasks that once required several workers for hours can now be completed by one person in minutes, greatly reducing labor costs.

The C72 also enables precise recording of wash cycles for each item. This data is analyzed to predict linen lifespan, allowing proactive replacement planning and maintaining appropriate stock levels—reducing delays caused by damaged or missing items.

During warehouse inbound and outbound processes, the C72 captures real-time inventory data, which is instantly synced to the backend system. This offers managers a clear, comprehensive view of inventory movement and enhances overall efficiency.

Additionally, the integration between the C72 and the client’s management system provides full traceability. If an item is misplaced or lost, managers can quickly identify the last recorded time and location, reducing losses and minimizing theft risks.

PDA Configuration

Model: C72

Functions: 2D Scanner, UHF RFID

Hubungi Kami Sekarang

Ingin menghadirkan event olahraga yang lebih akurat dan profesional?

Hubungi tim PT. Global Trend Asia, mitra terbaik Anda untuk solusi RFID & IoT Smart System di Indonesia.

Tim Sales & Marketing

Phone : +62 8222 100 8667

Email : sales@globaltrendasia.com